You don’t just “buy a light curtain.” You pick the right type for the hazard, the space, and the line speed. Let’s keep it plain: what the machine does, who gets near it, and how parts move should drive your choice. Below I’ll map the main categories to real shop-floor scenes, add quick tables, and point you to the right spot on our site when you’re ready to spec.

We’re NEW STAR OEM—your one-stop machine safety sensors manufacturer. We build Type 4 and Type 2 safety curtains with OSSD, EDM, restart interlock, muting/blanking, and custom options. If you need an odd size or a weird mounting, no panic—we do OEM/ODM.

Type 4 is the workhorse for higher-risk tasks. It offers stronger diagnostics and fault tolerance—ideal for presses, robot cells, and fast cycling equipment.

Type 2 suits lower-risk stations where you’ve got other risk reductions in place.

Quick pick: When unsure, go Type 4. It saves rework later.

See: Safety Light Curtains

Point-of-Operation (POC) curtains guard the actual danger point—press opening, mold area, pick window.

Perimeter Access Control (PAC) builds a virtual fence around the whole cell, aisle, or tunnel.

Resolution tells you the smallest object the curtain must “see.” Common breakpoints:

Smaller number = tighter grid = earlier stop. Match it to the body part that can reach the hazard.

See: High-Precision Safety Light Curtain (for finger) and General Use (for hand/body).

See: Multi-Sided Access Protection and General Use

When the frame is crowded—guard doors, pick stations, retrofits—you want slim housings:

These save your day when the last 10 mm decides everything. Alginment gets easier, too.

See: Compact Safety Light Curtain and Side/Front Ultra-Thin

If the machine shakes, throws debris, or lives near forklifts, pick the heavy class. If not, keep it simple.

See: Heavy Machine and General Use

Washdown zones, coolant splash, or dusty saw cells need sealed housings and protected windows. Look for:

Food & beverage, pharma, and wet machining really benefit here.

See: Waterproof Safety Light Curtain

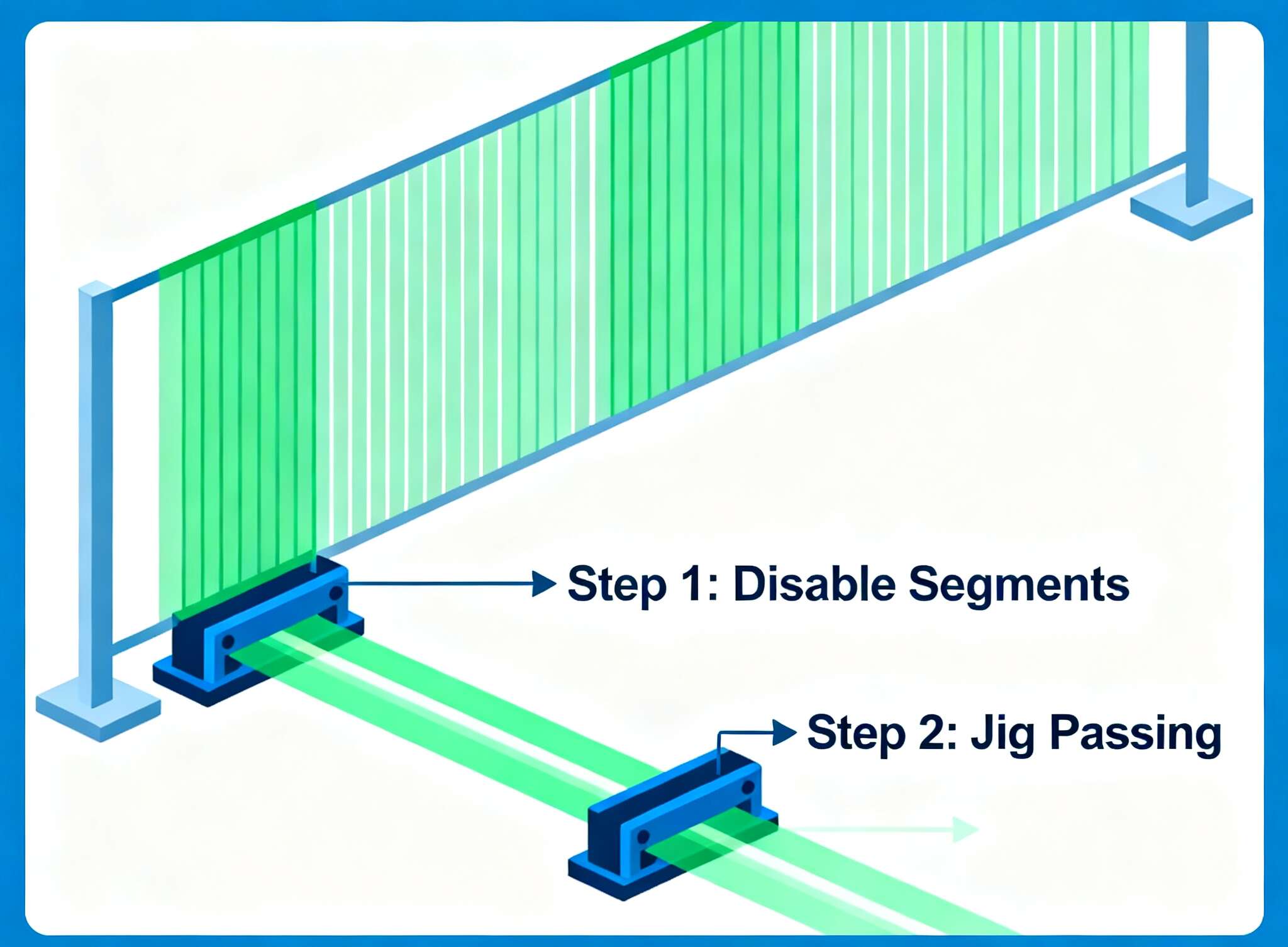

Instead of four separate systems, you can use corner mirrors to bend the beam around a cell. You get 2-, 3-, or 4-side coverage with one emitter/receiver pair.

See: Multi-Sided Access Protection

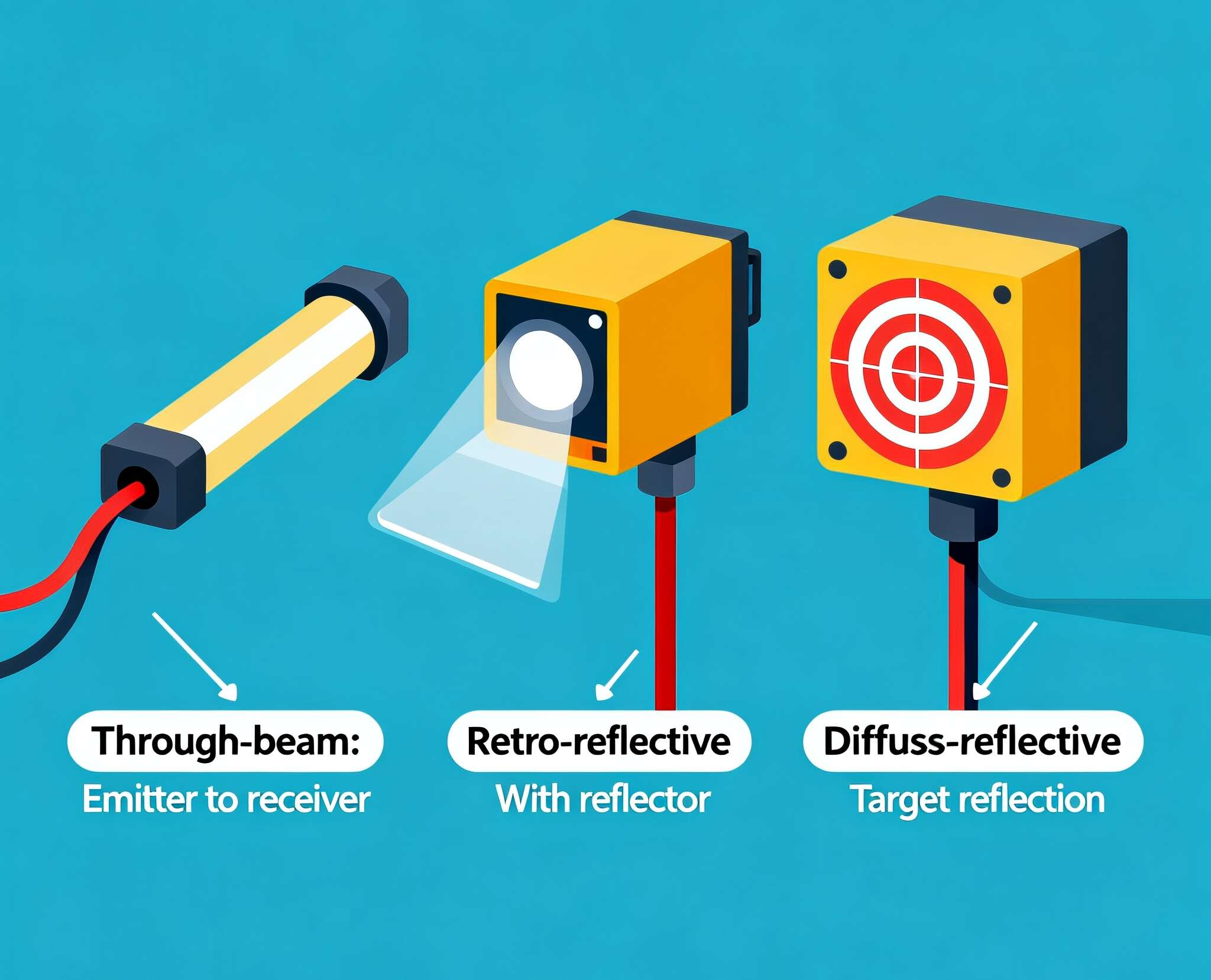

Different job. Measurement light curtains do profiling, DWS dimensioning, part detection, and flow checks. They’re for control and QA—not personnel protection. For guarding people, stick with safety models (Type 2/Type 4 with OSSD).

If your line needs both (size check + safe entry), we can pair a measurement curtain with a safety curtain, clean wiring, one bracket set.

We do odd heights, special beam pitches, bracket kits, field-bus gateways, and matched muting photoeyes. Need a non-reflective window for camera sightlines? A long-range POC with custom restart logic? We can tailor it. This is where bulk buyers and integrators save time across many cells. Yep, makes maintenance easier too.

See: Non-Standard / Custom Safety Light Curtain

| Type / Feature | Where it shines | Typical resolution | Mounting class | Function extras that help | Link |

|---|---|---|---|---|---|

| Type 4 (POC) | Presses, robot pick windows, die-cast | 14–30 mm (finger/hand) | Compact / Ultra-Thin | Restart interlock, EDM | Safety Light Curtains |

| Type 4 (PAC) | Cell perimeter, tunnel access | 30–50 mm (hand/body) | Heavy / General Use | Cascading, corner mirrors | Multi-Sided Access Protection |

| Type 2 (POC/PAC) | Low-risk stations with other controls | 30–50 mm | General Use | Manual reset, EDM | General Use |

| Waterproof IP67/IP69K | Washdown, coolants, dusty saw lines | 14–50 mm | Heavy / Compact | Window shields, sealed caps | Waterproof Safety Light Curtain |

| Ultra-Thin (Front/Side) | Tight frames, door edges, retrofits | 14–30 mm | Ultra-Thin | Quick-mount brackets | Side/Front Ultra-Thin |

| High-Precision | Small openings, fast stops, fine assembly | 14 mm | Compact | Diagnostics, fine alignment | High-Precision Safety Light Curtain |

| Custom / Non-Standard | Special heights, odd windows, bus I/O | 14–50 mm | Any | Muting kits, tailored logic | Non-Standard |

If you’re juggling E-stops, interlock switches, and scanners too, we also supply safety devices, photoelectric sensors, and flow sensors for your wider controls stack. One vendor, matching connectors, fewer headaches.