Light curtains are quick to install and easy to live with. But they’re not a wall, and they’re not a cure-all. If you treat them like solid guards or skip the safety math, you invite trouble. Below, I’ll walk through the real drawbacks, show where they bite on the shop floor, and note practical fixes. I’ll also point to the right NEW STAR families—because choosing the right type turns problems into non-issues (most of the time).

We sell Type 4 safety light curtains and companion gear at NEW STAR—OEM/ODM, ISO9001—so you can mix a simple, robust stack without drama. Browse the range: Safety Light Curtains.

A light curtain stops motion; it doesn’t stop shrapnel, sparks, chips, coolant splash, or kickback. If you grind, trim, saw, or de-gate, those “secondary hazards” still fly. So no, a curtain alone ain’t enough near abrasive wheels or hot trimming.

Mitigate: add fixed guards, clear shields, or interlocked doors where debris can launch. Keep the curtain for fast access; let the hard guard catch the nasty stuff. See Safety Light Curtains for the base families that pair well with doors and interlocks.

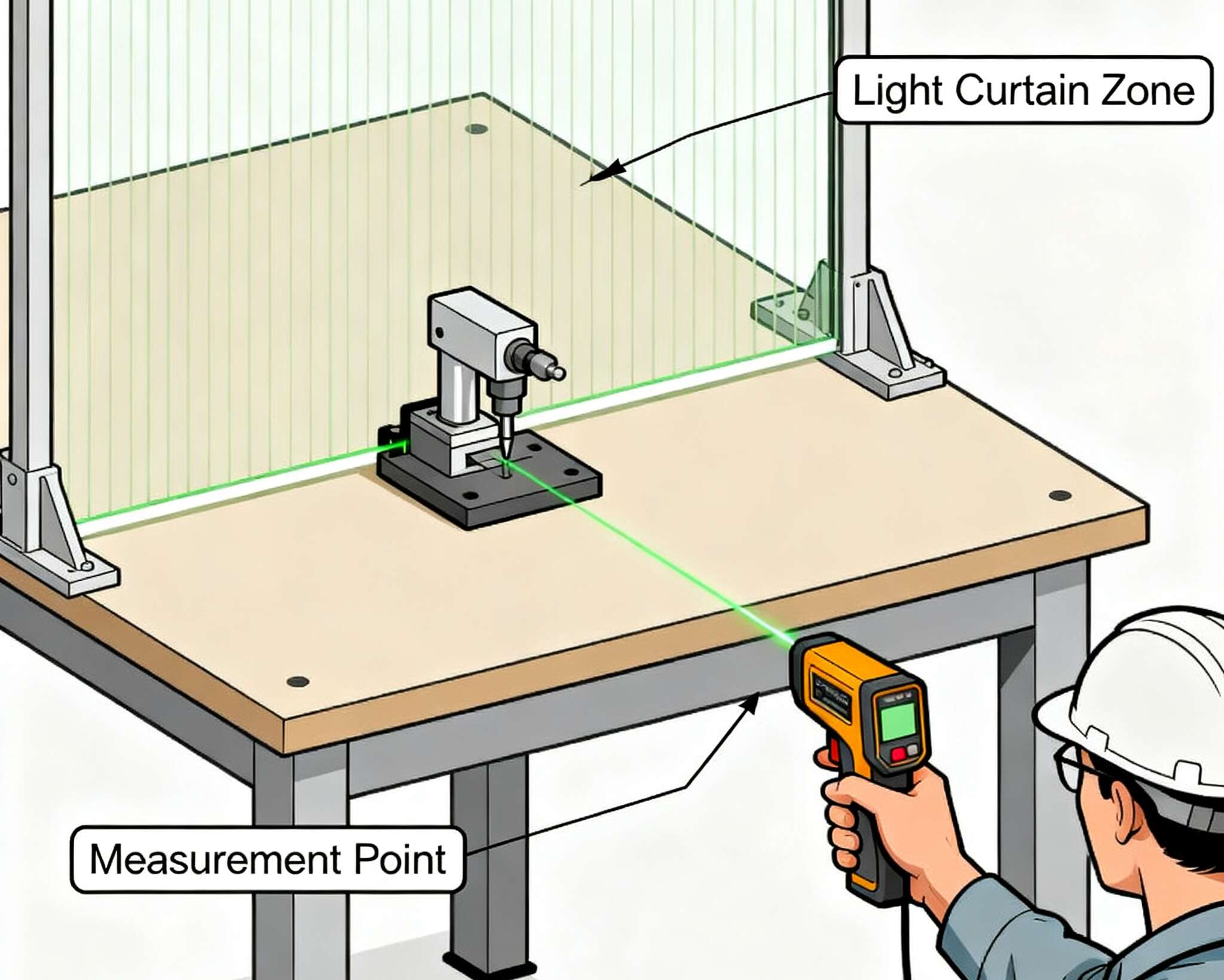

If you mount too close, an operator can reach the danger point before the machine fully stops. That distance depends on total stop time and beam resolution. Don’t eyeball it. Measure stop time, then set the curtain back far enough that reach-in can’t beat the stop.

Mitigate: when space is tight around a press or shear, use slimmer profiles to place the curtain where it fits and still meets the distance formula. Start with Safety Light Curtains and choose the right resolution for finger/hand/arm protection. (Short tip: finer resolution = closer mounting, but check the full stop chain.)

Light curtains need a clean line of sight. Mirrors, polished plates, shiny jigs, or wet floors can reflect beams and “cheat” coverage. Smoke, coolant mist, and wood/metal dust can attenuate light and cause nuisance trips—or worse, missed detection.

Mitigate:

Muting lets pallets pass; blanking ignores known fixtures. Both are useful. Both can open holes if you set them sloppy (long muting windows, wrong sensor geometry, static blanking where floating is required).

Mitigate: keep muting windows short, cross-check the muting sensors, and enforce restart interlock so the machine doesn’t auto-run after a trip. Pair curtains with a safety controller/relay that handles muting, EDM, and restart logic: Safety Device.

A curtain protects one plane. If someone can walk around, over, or under, you still have exposure. Big cells, wide conveyors, and robot hand-off corners are classic bypass paths.

Mitigate: close side gaps with screens or floor-level beams, or step up to multi-sided layouts inside Safety Light Curtains. For in/out tunnels, align curtains with guards so there’s no “free lane.”

The OSSD outputs are fast, but noise, poor grounding, or slow contactors can stretch the total stop time. Welding currents and VFD bundles near the signal cable? Yeah, that’s asking for false trips or delays.

Mitigate: route safety I/O away from power, bond grounds well, and use relays/controllers with EDM (External Device Monitoring). Keep non-safety counting off the safety chain—use dedicated sensors for that: Photoelectric Sensor for part detect, Measurement Light Curtains for profile/dimension, and keep your Type 4 curtain focused on guarding.

Brackets get bumped. Vibration loosens clamps. People stick tape flags for “temporary” hacks (don’t). Without checks, you get nuisance stops—or worse, blind spots.

Mitigate: write a five-minute routine: wipe lenses, verify alignment LEDs, and run a trip test with a test rod at the start of the shift. For splashy lines, pick sealed models from Safety Light Curtains and put a blow-off nozzle over the lens. Simple stuff, big wins.

Old full-revolution presses can’t stop mid-stroke. Massive flywheel systems take long to halt. In those cases, a light curtain at the point of operation doesn’t fit the risk.

Mitigate: switch to perimeter guarding or interlocked doors plus two-hand control where required. Use a safety controller with proper feedback and diagnostics: Safety Device. If you still need part detection, offload it to Photoelectric Sensor and keep safety logic clean.

| Drawback (keyword) | Why it matters | Typical scene | Practical fix | Source |

|---|---|---|---|---|

| No physical barrier | Stops motion, not debris; chips/sparks still fly | Grinding, trimming, sawing | Add fixed guards/doors; keep the curtain for access | Safety Light Curtains |

| Safety distance (ISO 13855) | Too close = reach-in beats stop time | Presses, shears, high inertia | Measure stop time; set back; pick right resolution | Safety Light Curtains |

| Reflection / smoke / dust | Optics fooled or attenuated | Polished tables, coolant mist, sanding | Matte surfaces; sealed IP variants; clean lenses | Safety Light Curtains |

| Muting/blanking mis-set | Throughput logic opens a hole | Pallet conveyors, auto in-feed | Short muting window; cross sensors; restart interlock | Safety Device |

| Bypass around plane | Over/under/side gaps remain | Wide cells, tunnels | Side screens; floor beams; multi-sided layouts | Safety Light Curtains |

| EMC & control chain | Noise or slow contactors stretch stop | Weld bays, VFD clusters | Clean routing/ground; EDM feedback; split tasks | Safety Device |

| Separate detection needs | Safety chain gets overloaded | Counting, profiling, DWS | Use non-safety sensing for process | Measurement Light Curtains, Photoelectric Sensor |

Packaging & logistics

Pallet muting works… until a wide tote tails a pallet through a long muting window. People follow. Fix the geometry, shorten the window, and enable restart interlock in the Safety Device controller. If you also need carton width/height, let Measurement Light Curtains handle it so safety logic stays simple.

Stamping & metalworking

Chips and slivers still fly. Add a clear shield or door near the die, then place the curtain where the distance math says. Thin profiles inside Safety Light Curtains help when brackets fight you for space.

Injection molding / die casting

Mist loves optics. Random trips follow. Use sealed windows, add a weekly wipe, and keep part presence on Photoelectric Sensor so you’re not stuffing non-safety checks into the OSSD chain.

Robot cells with hand-offs

There’s always that side gap by the post. Close it. Add a low beam or go multi-sided with the curtain layout from Safety Light Curtains. Tie everything into EDM so welded contactors don’t slip by.

Woodworking & board cutting

Dust clouds beams and makes operators curse. Use a light air knife across the lens, sealed models, and do a fast daily trip test. No magic here, just care.