Short answer: it depends on optics, beam pitch, alignment, and the messiness of your plant. Range isn’t one magic number; it’s a working window you size for your cell. Let’s keep it plain, show the levers that move range, and map those levers to real factory scenes.

NEW STAR is a one-stop machine safety sensors manufacturer (ISO 9001 factory; EU Type 4 capability) with OEM/ODM from sample to scale. That matters when you need a curtain that fits your line, not the other way round.

Safety Light Curtains (All) · Front Ultra-Thin · General Use · Heavy Machine · High-Precision · Multi-Sided Access Protection · Waterproof Safety Light Curtain · Measurement Light Curtains

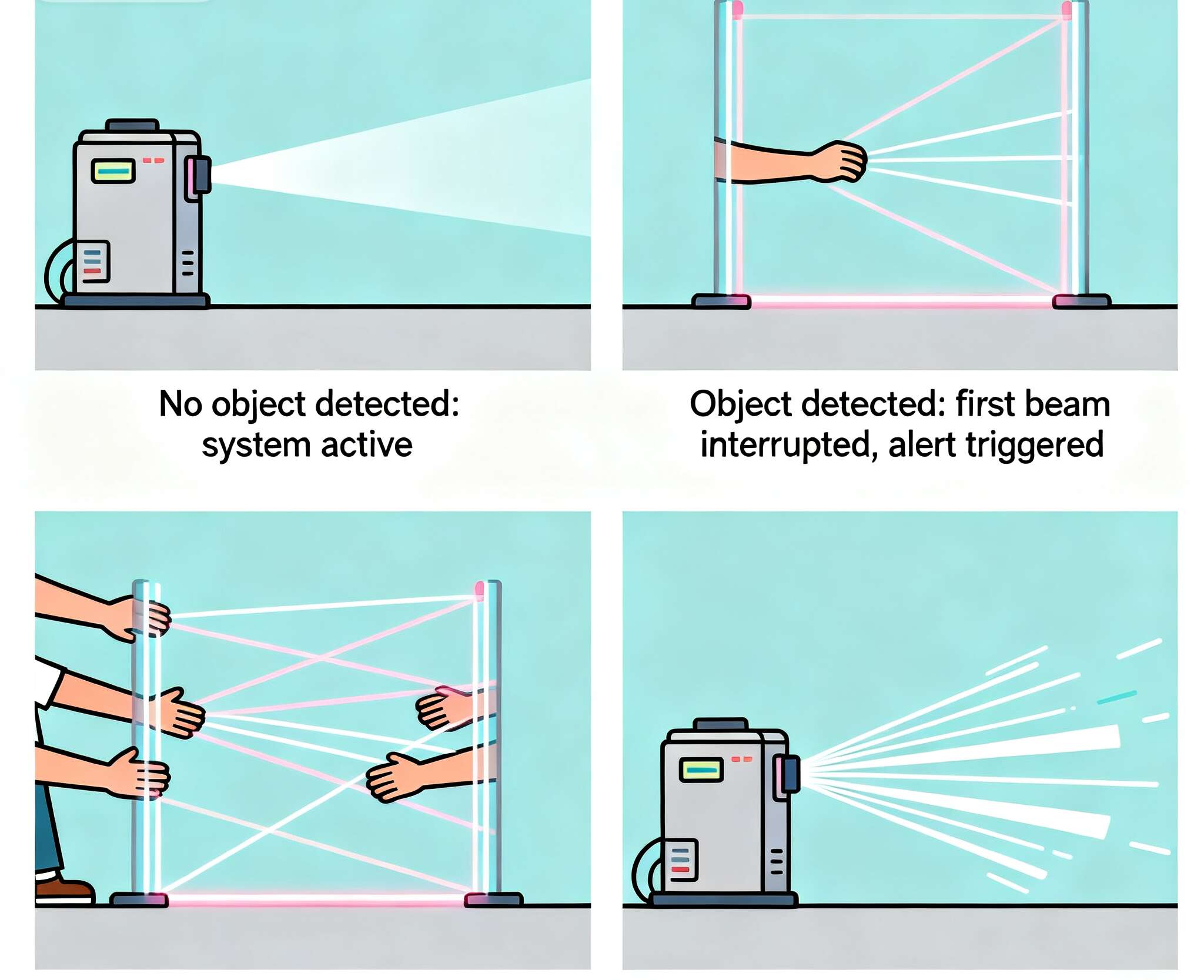

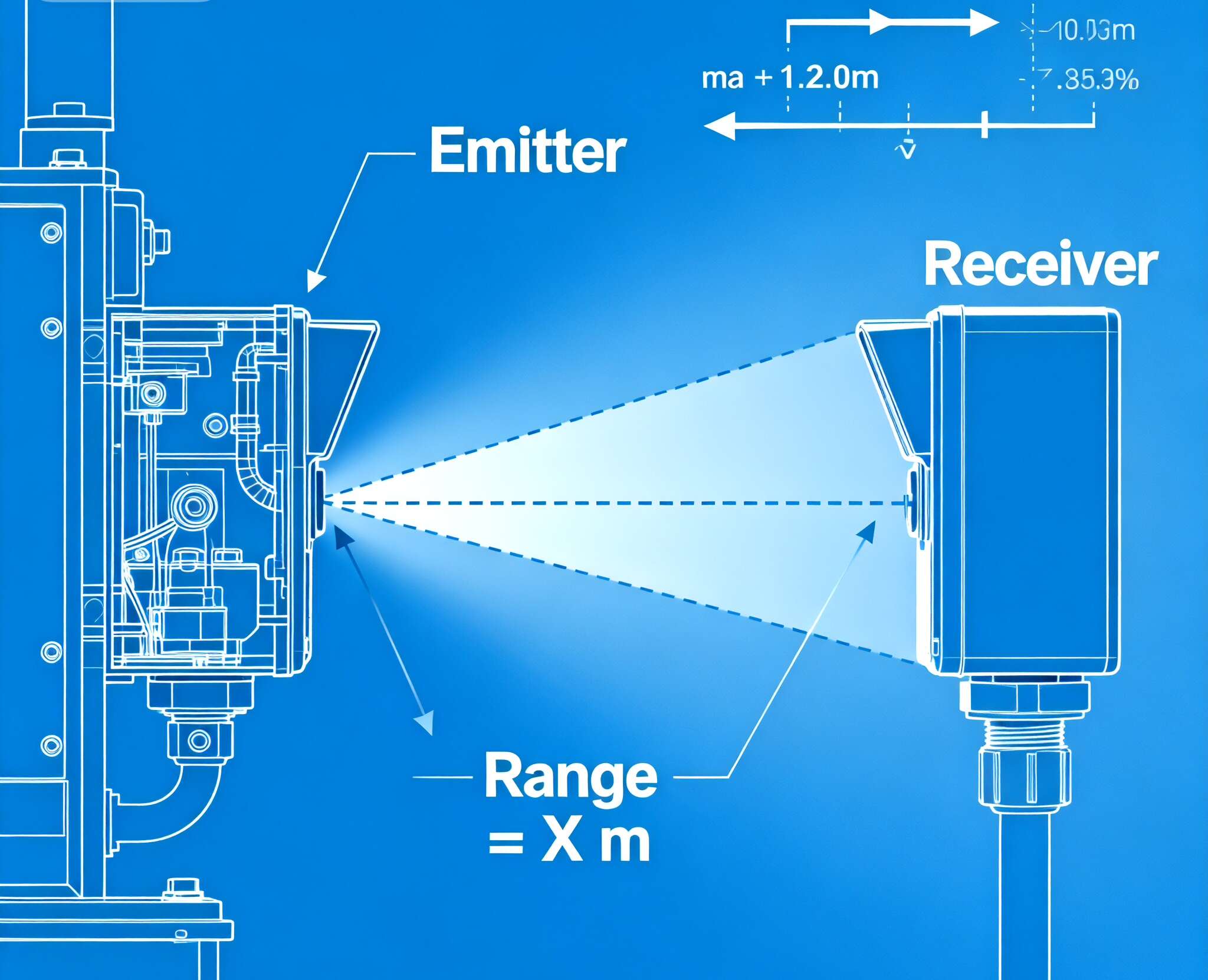

Operating range is the maximum transmitter-to-receiver distance where the curtain still detects reliably. You confirm it after you pick resolution (finger/hand/body), protective height, feature set (muting/blanking/EDM), and sealing (IP67/IP69K). Then you install, align, and keep the optics clean. Simple, not fancy.

You choose beam pitch first because it defines what you catch. Finger protection (tight pitch) sees smaller intrusions but can demand tighter alignment and cleaner windows. Hand/body grids are more forgiving and often support longer spans. Don’t over-spec the pitch if you don’t need it; save margin for mirrors and dust.

Type 4 gives you higher diagnostic coverage and stable OSSD behavior. In plain talk: fewer nuisance stops at distance. For heavy equipment or robots, most teams stick to Type 4 with PL e / Cat. 4 architecture and proper MPCE monitoring. Ya, it’s stricter—for a reason.

Water, steam, oil, and alkaline foam scatter light and chew up range. Waterproof bars with sealed fronts (IP67/IP69K) hold alignment better under washdown. Add a cleaning routine; you’ll keep your detection headroom.

Not every job needs “max range.” You want enough range with margin, matched to your scene and risk.

| Scene / Use case | Practical range bucket | Pain point from the floor | Suggested NEW STAR family |

|---|---|---|---|

| Tight doors, cabinets, small frames | Near-field | Shallow depth, cable crowding, finger safety | Front Ultra-Thin |

| Standard guarding on presses, brakes, molds | Mid-range | Stable alignment, hand/body grids, quick changeovers | General Use |

| Harsh cells: stamping, forging, long conveyors | Long-range | Dust/oil mist, vibration, corner mirrors | Heavy Machine |

| Close to hazard with finger detection | Near- to mid-range | Tight pitch, false-trip control, EDM | High-Precision |

| Washdown (dairy/beverage/CIP) | Near- to mid-range | High-pressure spray, chemical foam | Waterproof Safety |

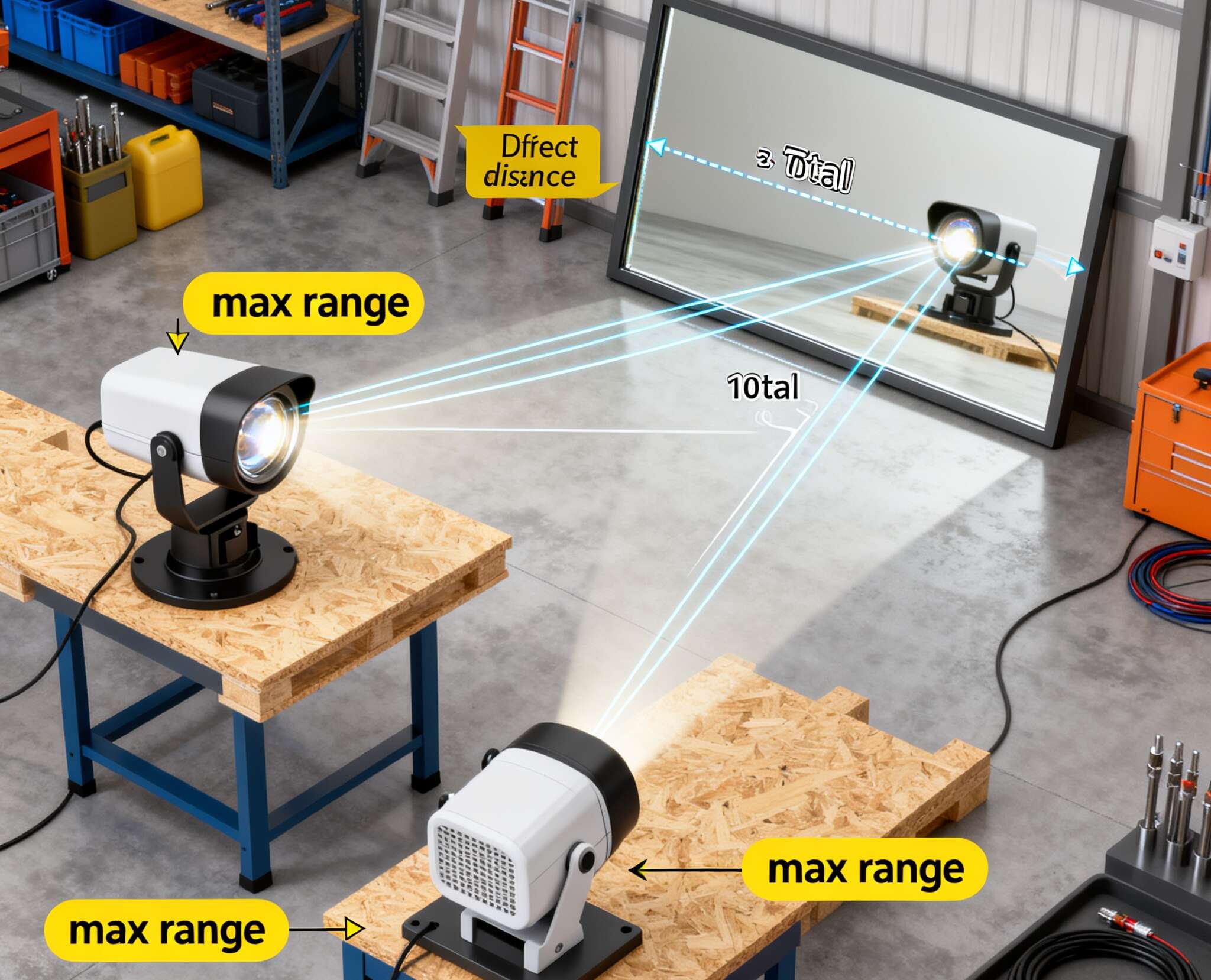

| Perimeter with mirrors (2–4 sides) | Mid- to long-range | Each mirror adds loss, needs headroom | Multi-Sided Access |

| Factor | Impact on range | What you do about it | Where to start |

|---|---|---|---|

| Beam pitch / resolution | Finer pitch can reduce distance tolerance | Pick the coarsest pitch that still meets risk | High-Precision or General Use |

| Optical power & mechanics | More robust optics hold alignment over time | Choose reinforced housings and solid mounts | Heavy Machine |

| Sealing & window cleanliness | Oil/steam scatters beams and eats margin | IP67/IP69K and a cleaning routine | Waterproof Safety |

| Mirrors / multi-side layouts | Each mirror adds optical loss | Start with long-range optics; verify on site | Multi-Sided Access |

| Diagnostics & features | Better self-check = fewer nuisance stops | Use OSSD, EDM, muting/blanking the right way | General Use |

| Controller integration | Poor wiring = flaky trips | Keep MPCE, RI, and reset logic clean | Any Type 4 family |

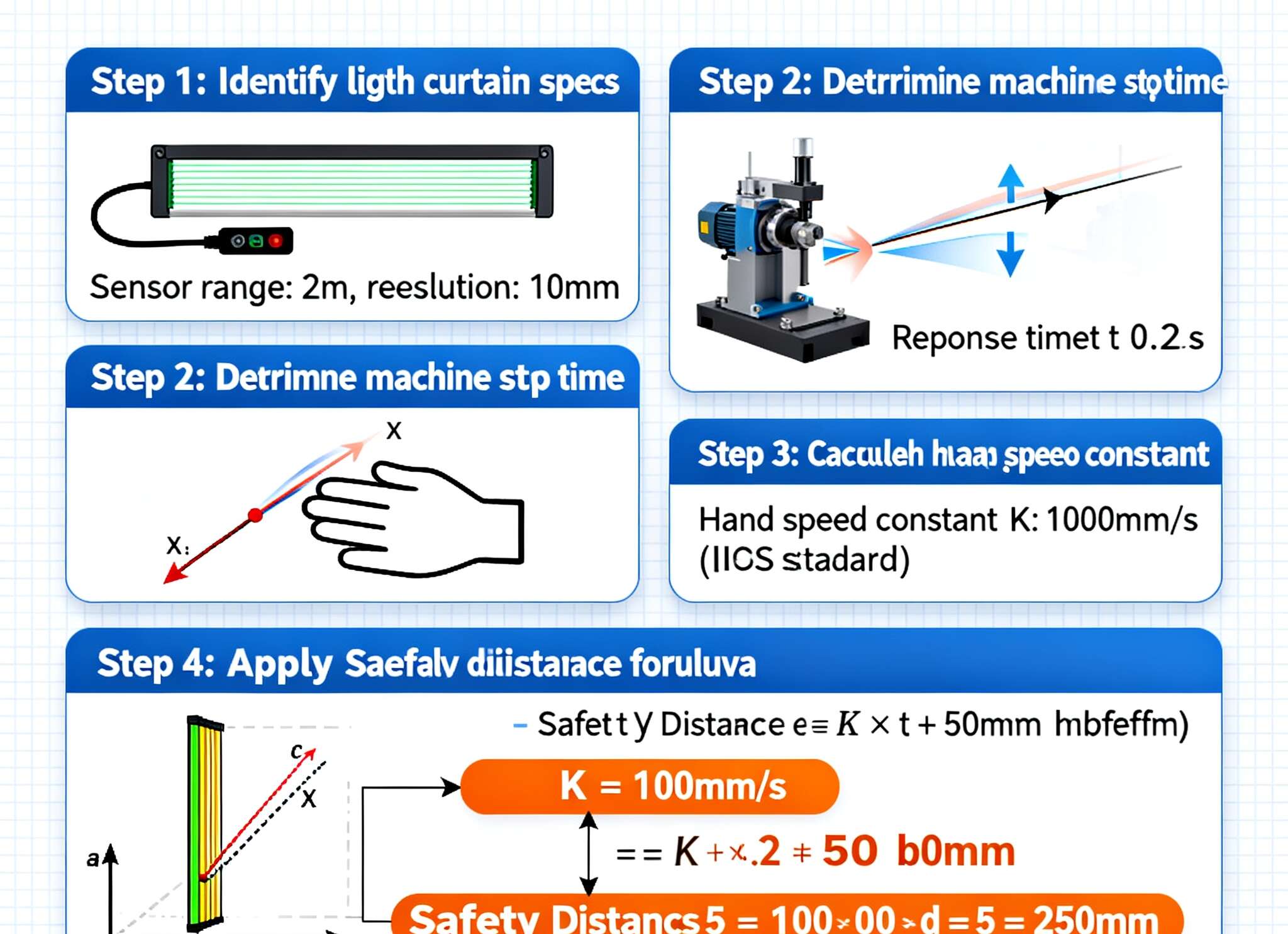

Range tells you how far the bars can face each other and still detect. Safety distance tells you how far the curtain must sit from the hazard so a person can’t reach it before the machine stops. You size safety distance with the standard method (think ISO 13855) using machine stop time, curtain response, and resolution. Different math, different purpose. Don’t swap them.