When you put a safety light curtain in front of a press, robot, or conveyor infeed, you’re not just installing a sensor.

You’re deciding how much time the machine has to stop before a hand, arm, or full body gets into the danger zone.

That’s why machine stop time and safety distance always travel together. If the machine needs more time to stop, you must place the light curtain further away. If you shorten the stop time, you can move the curtain closer and still stay inside EN ISO 13855 and ANSI B11.19 rules.

Both main standards use the same basic idea:

The common formula looks like this:

Where:

ANSI B11.19 just breaks T into more pieces (machine stop time, control time, light curtain response, brake monitor, etc.), but for a daily engineering talk you can think of it as one total stop time.

A simple way to read it:

if T doubles, and everything else stays the same, S almost doubles.

That’s the “versus” in stop time vs safety distance.

| Symbol | Meaning on the shop floor | What you usually check |

|---|---|---|

| S | Safety distance | Where you mount the curtain |

| K | Human approach speed | Hands vs walking body speed |

| T | Total stop time | Light curtain + control + machine |

| C | Penetration distance | Depends on resolution and body part |

This table looks simple, but it drives every serious project, from a small press upgrade to a full robot line.

Many teams still look only at “brake time”. That’s risky.

Total stop time T must include:

If you ignore the electronic parts and only measure the press brake, you under-estimate T. Then you mount the curtain too close. On paper the math looks fine, in reality the operator can still reach the hazard before motion hits zero.

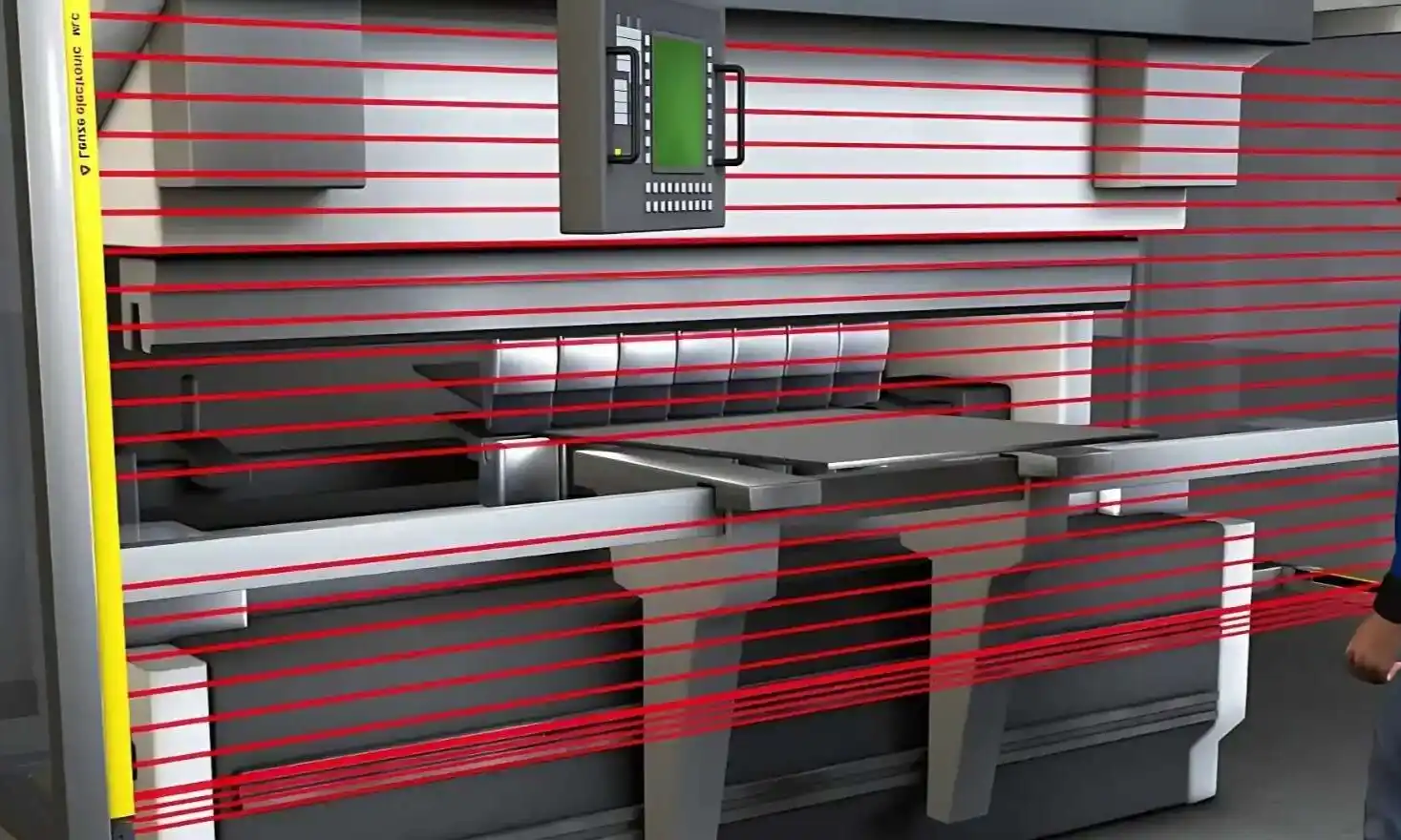

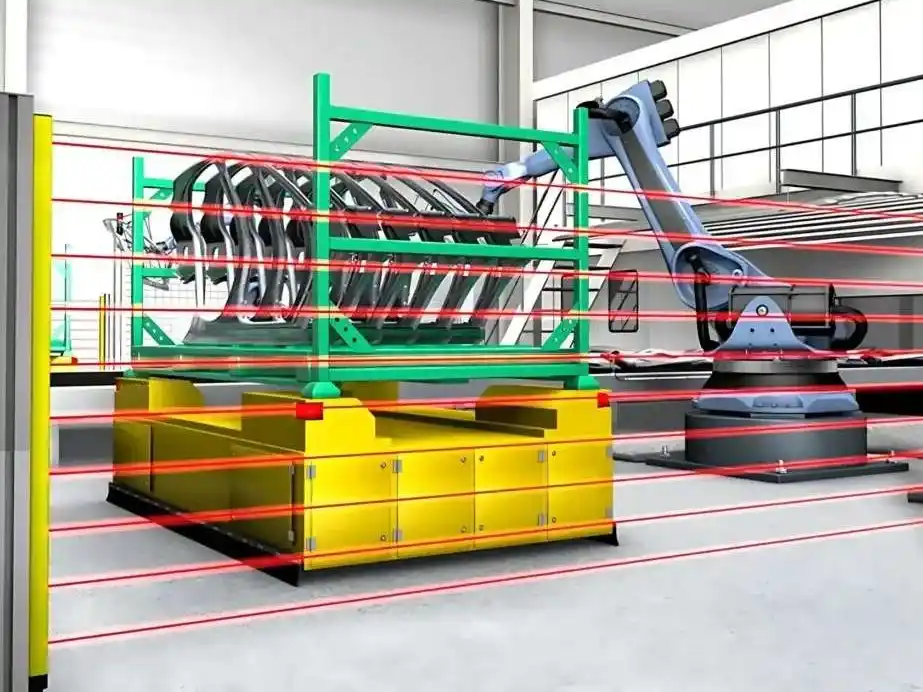

This is exactly where a fast Type 4 safety light curtain helps. With products like the DGD1220 machine safety light curtain or the ultra-thin DCBZ1240 infrared curtain, the sensor response time stays low, so more of your “time budget” belongs to the machine stop, not the electronics.

Penetration distance C tells you how far a body part can pass into the light curtain field before the beams actually see it. That number changes with resolution:

So even if machine stop time T is the same, a high-precision safety light curtain can allow a smaller S than a body-protection grid.

NEW STAR’s product tree is built around these different needs:

Picking the wrong resolution means you fight against the formula every time you try to set the mounting distance.

On real equipment you shouldn’t guess T. You measure it.

Typical cases where stop time measurement is a must:

A simple workflow many safety and maintenance teams use:

You’ll see this alot in plants where EHS and maintenance work close together. The machine feels “fine”, but the measured T gets longer over time. Without updating the light curtain distance, the original risk analysis is already outdated.

Stop time and safety distance are safety topics, but they directly touch productivity and ergonomics.

On a packaging or logistics system, if stop time is long, the formula forces you to mount the curtain far from the nip point or robot. That means:

Here’s a quick view of how operators feel different combinations.

| Stop time and distance | How it feels for the operator | Typical equipment |

|---|---|---|

| Short T, small S | Curtain close to hazard, easy reach, less walking | New servo press, tight robot cell, high-precision curtain |

| Medium T, medium S | Guarding ok, but some extra movement | Standard palletizer, injection molding machine, small assembly line |

| Long T, big S | “Why is this so far away?” more walking, more fatigue | Older crank press, long conveyor cells, big gantry robots |

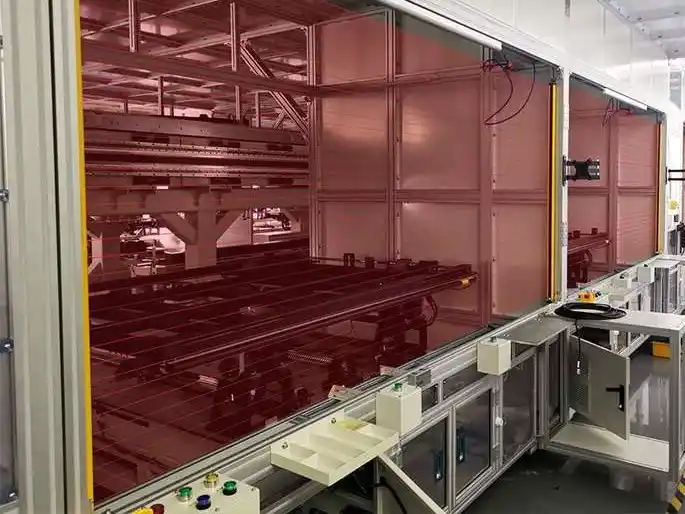

In food, beverage, and washdown zones you get another twist. You need IP-rated safety curtains, so stop time, S, and environment all collide. That’s exactly why solutions like the SWP2840 industrial light curtain exist: proper waterproof housing plus the response time you need for a reasonable distance.

Sometimes you run the full calculation with real T, and the result looks impossible. Maybe the curtain would end up in the walkway, or right in front of a pallet lane. You still have options, you dont must accept it.

This is a pure engineering job:

Shorter T means smaller S, without changing the light curtain type.

If current guarding is more like body detection, C is large. Switching to a high-precision curtain or a compact Type 4 model can reduce C and bring the curtain closer to the hazard.

For example:

When you design both T and C smart, the light curtain placement becomes a tool for safety and for better takt time, not a barrier.

NEW STAR positions as a one-stop machine safety sensors manufacturer, with ISO9001 factory and OEM/ODM capability from single sample to mass batch. That sounds like marketing, but it actually matters for stop time and safety distance:

When automation engineers talk about EN ISO 13855, EHS talks about risk reduction, and purchasing talks about delivery and batch orders, everyone is still looking at the same hardware family on thelightcurtains.com.

Before you sign off the next cell or line, run through this quick list:

If you can tick those points, your stop time vs safety distance story is in much better shape. And when you want that story to connect to real hardware, OEM customization, and wholesale batches, you know you can grab it straight from thelightcurtains.com.